Flange Facing

Flange Facing

Regular flange face maintenance plays a crucial role in ensuring the efficient, safe, and eco-friendly operation of your plant. By opting for flange facing as a proactive and preventative measure, you invest in a longer-lasting solution that is not only more cost-effective than leak-sealing methods but also proves to be more affordable than a complete flange replacement.

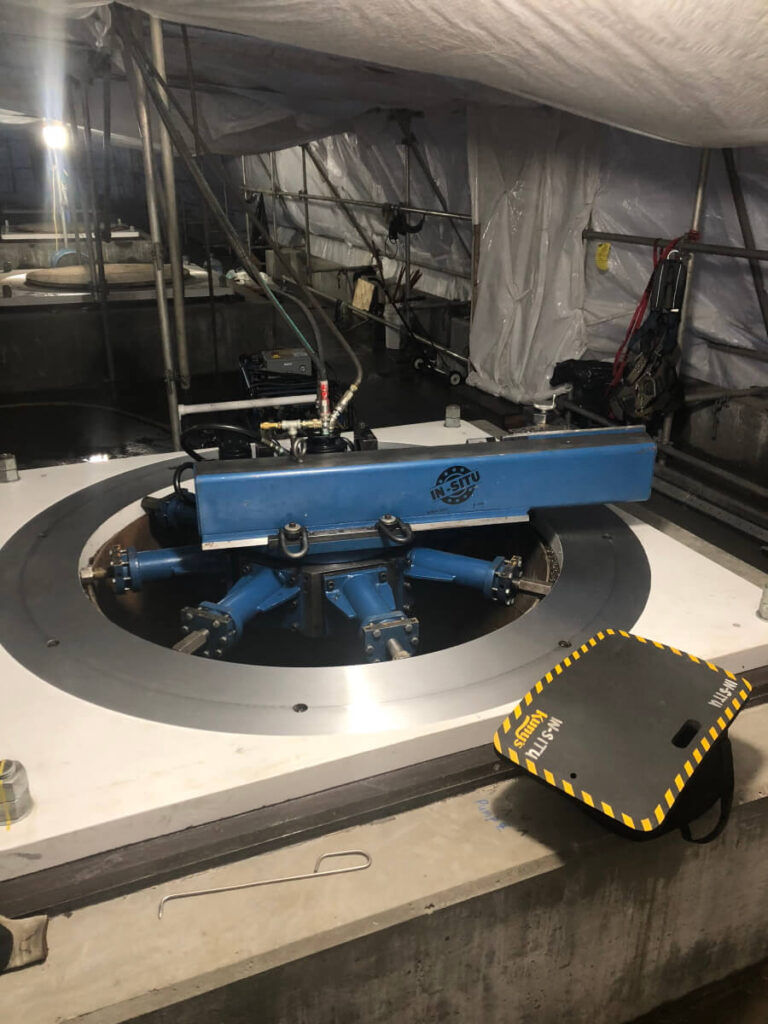

In-Situ Machining Solutions proudly offers an extensive range of budget-friendly services for the maintenance and restoration of flange faces, accommodating diameters ranging from 0 to 156 inches. Our machines are not only lightweight and portable but also designed to fit in even the most challenging and hard-to-reach locations.

We are committed to minimizing any disruptions to your operations by efficiently completing most jobs during your scheduled downtime. This approach allows us to effectively restore your flange faces without causing any unnecessary delays or hindrances to your plant’s productivity.

By choosing In-Situ Machining Solutions for your flange face maintenance needs, you can be confident in our ability to deliver exceptional results while prioritizing the safety, efficiency, and sustainability of your plant’s operations.

Flange Facing Services

- Raised Face Flanges

- RTJ Flanges

- Lens Ring Flanges

- O-Ring Groves

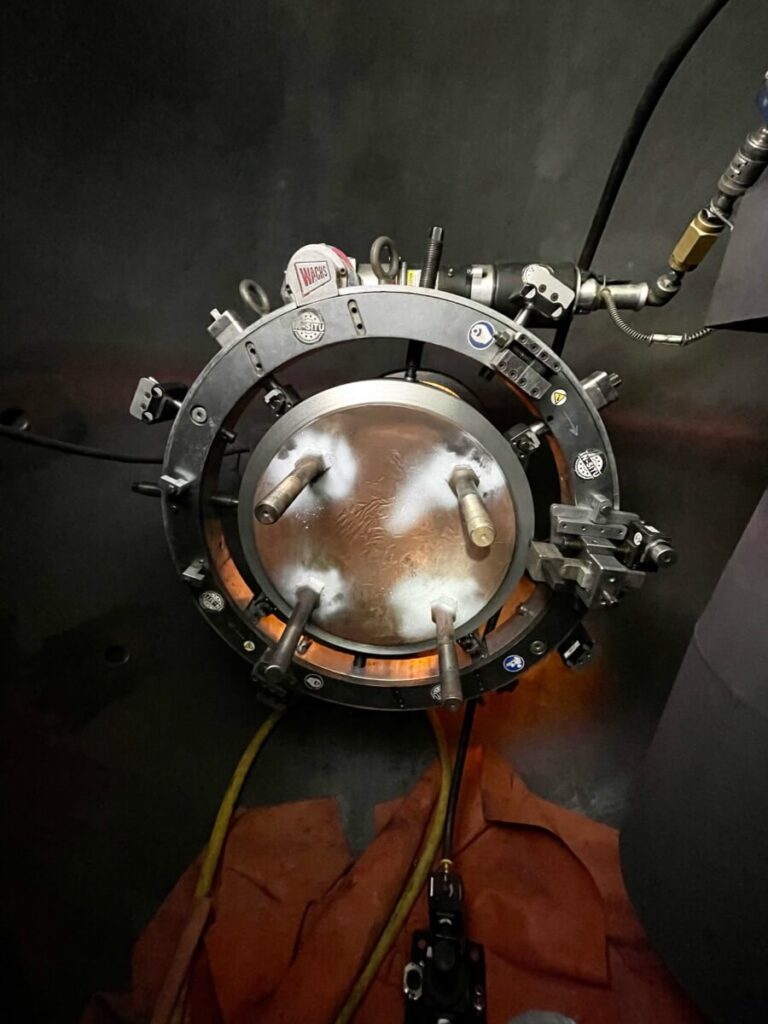

- Oval Manways

- Flat Face Flanges

- Greyloc Connections

- Fire Tube Shell Flange

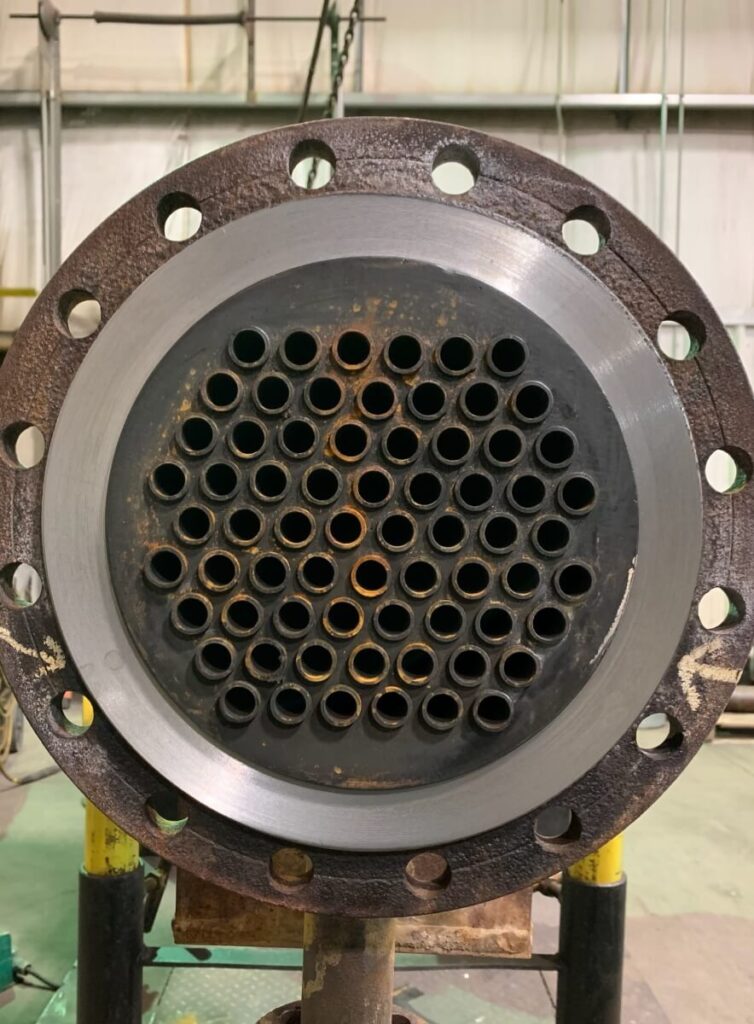

- Exchanger Flanges including:

- Tube Sheets

- Channel Heads

- Shells

- Dollar Plates

Flange Facing Machine Specs

ID Mounting Flange Facers

| Machine | Diameter |

|---|---|

| FF 10 | .900” – 10” |

| FF 1000 | 0″ – 8″ |

| FF 3000 | 2″ – 12″ |

| FF 5000 | 8″ – 20″ |

| FF 5300 | 10″ – 35″ |

| FF 6000 | 20″ – 50″ |

| FF 6300 | 12″ – 57″ |

| FF 7200 | 35″ – 80″ |

| FF 8000 | 40 – 156″ |

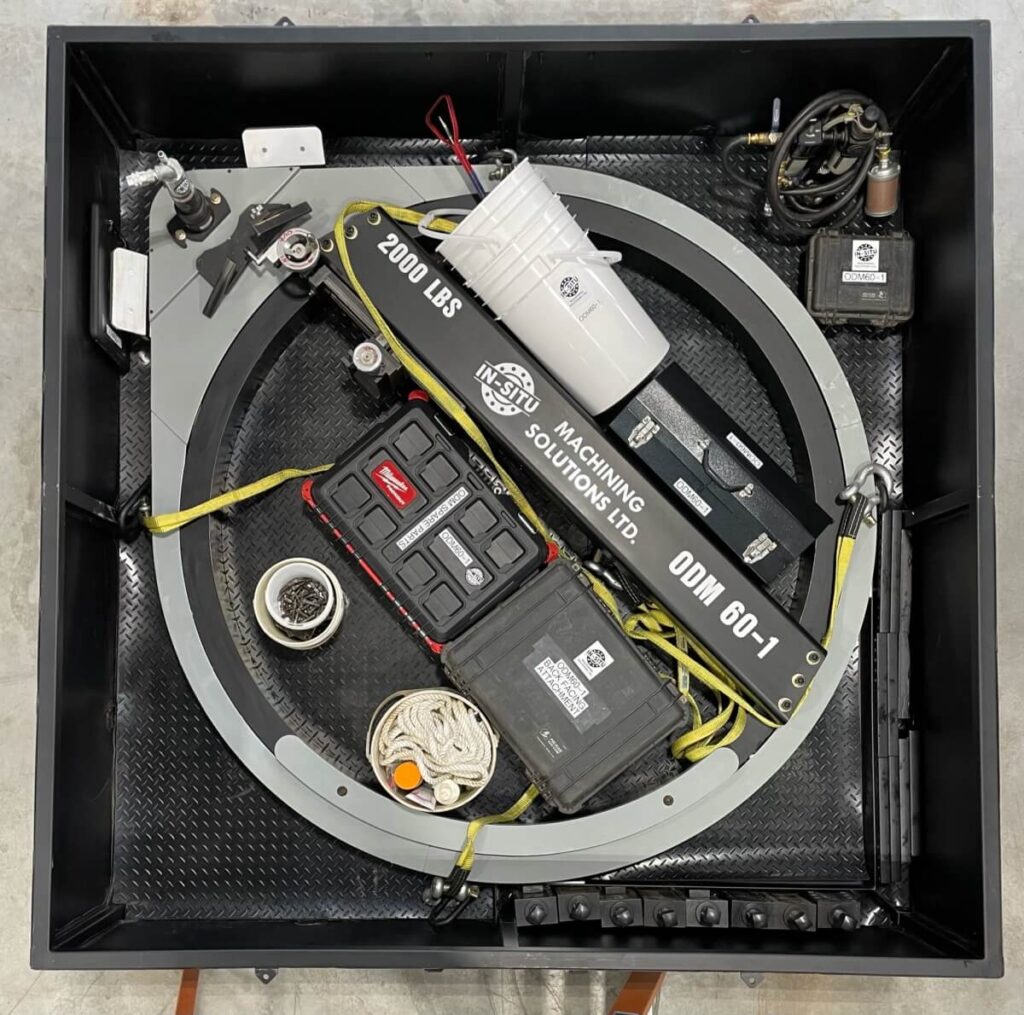

OD Mounting Flange Facers

| Machine | Diameter |

|---|---|

| ODM 13 | 0″ – 15″ |

| ODM 30 | 15″ – 30″ |

| ODM 40 | 20″ – 40″ |

| ODM 50 | 30″ – 50″ |

| ODM 60 | 40″ – 60″ |

| ODM 70 | 50″ – 70″ |

| ODM 80 | 60″ – 80″ |

Flange Facing Tools & Equipment